This month we continue our 3 part series on engineering efficiency in completion operations with addressing acid displacement in frac pump times. Applying new concepts in acid displacement during wireline pump down operations allows us to place acid near the perfs, or displace acid entirely, after perforating for a stage. Doing this decreases the pump time for a stage by increasing the overall average rate. Shorter pump times allow for more stages pumped per day.

Spearheading acid into a frac has been a pretty common practice for some time now. We have started stages by getting injection and then swapping over to acid. But why haven’t we considered taking this step out of our frac pump times?

Pumping acid at the start of the frac simply costs pump time. We are limited on rate while pumping acid due to surface equipment and the extra friction pressure that acid creates when displacing in the wellbore. Taking this into consideration we can start to analyze the cost difference when pumping acid during or after our wireline pump down operations.

Let’s breakdown the time it takes to pump 50 bbls of 15% HCL at the start of a frac in a 5.5” 20# casing string with a WBV of 250 bbls. When starting a frac we are pumping water to ensure injection before swapping over to acid. Once on acid the pumps are limited to 8-12 bpm; this is due to the max allowed rates for suction/discharge hoses as well as the rate the acid pump can maintain. (~5 mins)

After swapping back to water we now must displace the acid. Here is a breakdown of the fluid friction at different rates. At 20 bpm 15% HCL produces 2.351 psi/bbl, 40 bpm it produces 8.277 psi/bbl, & 60 bpm it produces 17.352 psi/bbl when being pumped in this 5.5” casing. Compare this to 20 bpm 1 gpt FR slickwater produces 0.847 psi/bbl, 40 bpm it produces 2.332 psi/bbl, & 60 bpm it produces 4.255 psi/bbl.

So, for a 50 bbl slug of acid at 60 bpm there will be an increase of ~650 psi in friction compared to pumping 1 gpt FR slickwater. Meaning without the 50 bbls of acid we could easily obtain 82.5 bpm with a 650 psi increase in friction with a 250 bbl WBV of all slickwater (6.872 psi/bbl at 82.5 bpm). That is a difference of 22.5 bpm which adds up in time as well. (~1.5 mins)

Fluid Friction Calculations:

For a 5.5” 20# casing string with a WBV of 250 bbl

At 60 bpm with 50 bbls of 15% HCL & 200 bbl of 1 gpt slickwater,

1719 psi = 50 bbl HCL x 17.352 psi/bbl + 200 bbl SW x 4.255 psi/bbl

At 82.5 bpm with 250 bbls of 1 gpt slickwater,

1718 psi = 250 bbl SW x 6.872 psi/bbl

Reference: BJ Services. Electronic Engineering Handbook. 2nd edition. Houston, TX. (2010) “Acidizing; Calculators; Fluid Friction”

Looking at our time breakdown it is easy to determine that pumping acid does add up for frac pump times. On average pumping acid at the start of a frac can add 6.5 minutes of unnecessary pump time. By removing this time we create efficiency by minimizing pump times and creating opportunities for more stages by increasing the overall average rate for each stage.

Removing acid from our frac pump times means we must remove it from frac operations entirely. There are several ways we can do this, but we will address two ways that we see beneficial.

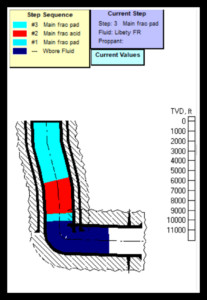

Green or Safe Acid is a new phrase that we have been hearing of more often. Our first experience utilizing Safe Acid was in 2019 and we immediately saw the benefits. Safe Acid is a safe alternative to hydrochloric acid because it is formulated to be less corrosive and does not cause skin irritation according to the manufacturers. Because of this we can pump safe acid down and around the wireline cable & tool string while doing the pump down. We can also leave safe acid in the wellbore so frac can finish displacing at the start of that stage.

Depending on the flush and pump down volumes as well as utilizing ball in place we recommend pumping the safe acid while the plug & guns are falling in the vertical. This may not be possible during toe stages due to pump down volumes exceeding flush volumes; doing this would result in displacing the safe acid into the previous stage. We do this so that the safe acid is close to the perforations after we finish the plug & perf run for that respective stage. At this point we can either choose to finish displacing the acid at 22 bpm with pump down (once wireline is at surface) or we can let frac finish displacing the acid at higher rates to maintain perf friction while displacing.

Another way is utilizing the conventional hydrochloric acid. We are unable to pump HCL around the wireline cable & tool string or leave the acid in the wellbore without concerns of corrosion. Therefore, we must wait til we finish the plug & perf run and for wireline to return to surface before we can swap over to acid. Doing it this way we do have to add a step to our pump down operations by removing wireline from the well before displacing acid. Although this is an economic way to remove acid pump times from the frac this step also takes more water and diesel than utilizing the Safe Acid. However, we still use the same amount of water and fuel that would be needed if the acid was pumped during frac operations.

Overall, choosing to take acid out of the frac pump times and move over to the wireline pump down operations will always save time and money. Saving 6.5 minutes per stage can add up when pumping 10-14+ stages per day.

If this something you would like to integrate into your operations and would like a more detailed procedure then contact us at info@xstimconsulting.com. Let us know how we can help you bridge the gap from engineering to operations.

Learn More: Valve Efficiency, Consultant of the Month, ZipVision